Orinox reinvents Operator Training and Safety induction

Our solution enables operation managers and instructors to :

- create interactive scenarios: Trainees can be trained in the most difficult procedures in the most hazardous situations in perfect safety.

- create 3D contexts: This allows instructors to present complex and/or critical situations to trainees, in order to train them and interact with them about solution and decision to make.

- create cinematic scenarios: Here, trainers can create several combinations of movements or elements, in tiny spaces not really accessible or too risky space where people can't stay long.

ORINOX Simulation offers a solution for that improves efficiency, security & productivity

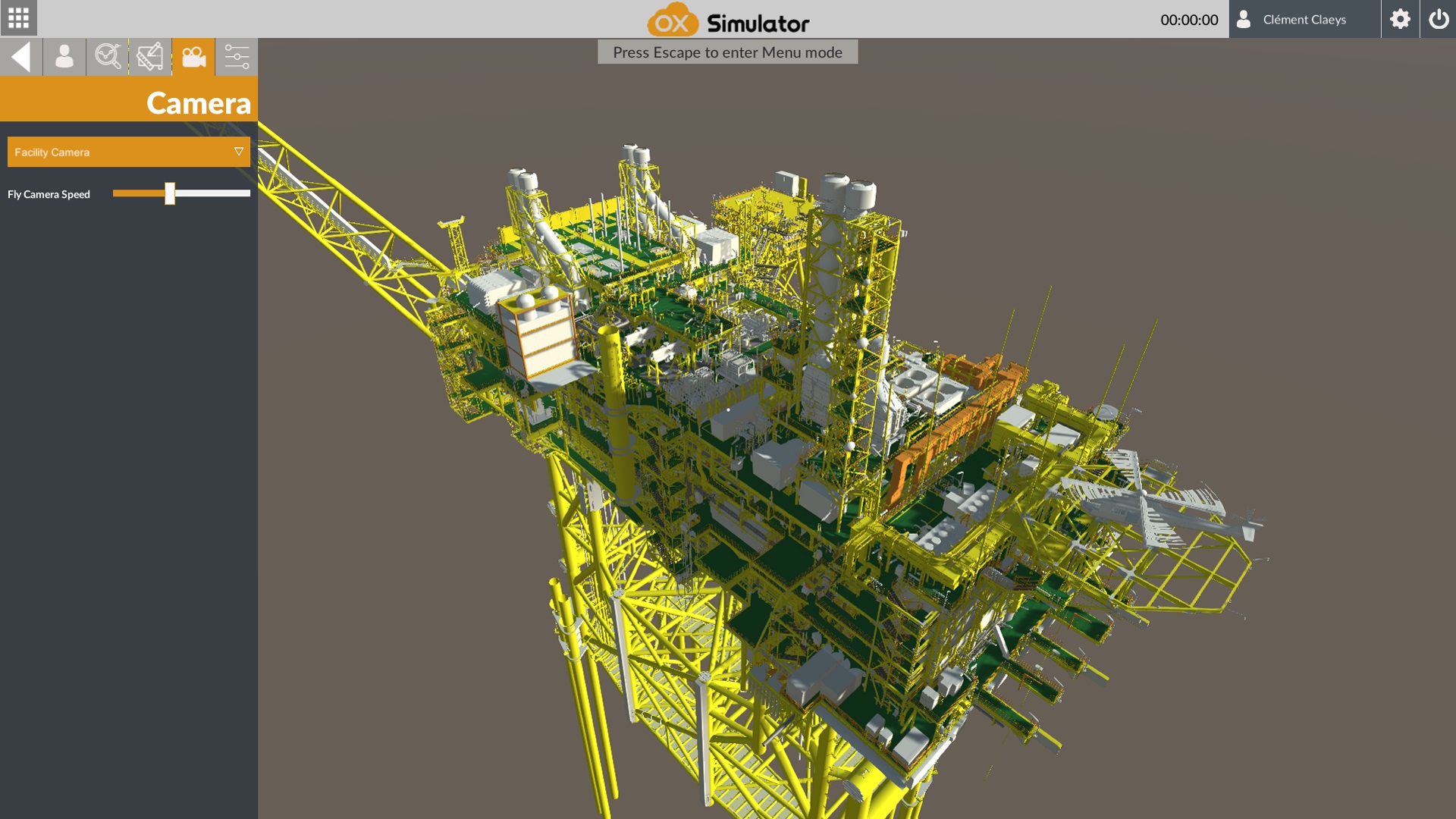

From training procedures and a 3D model (CAD or from a laser scan), you can create yours 3D scenes.

ORINOX ITS app offers a multitude of innovative functions: visualize industrial plant ergonomics, gain in-depth operator knowledge of the plant, simulate vehicle operation on-site, manage night and day functions, operate in the same environment with multiple users charged with different roles, access the entire Digital Asset (P&IDs, constructor documentation, construction videos about equipment...), test operator knowledge about PPE (Personal Protective Equipment), and many more.

Collaborative

Experience collaborative engineering on an adapted data portal, and share data within all the project teams.

Secure

ORINOX Simulator runs with ORINOX Cloud Web Services powered by Amazon Web Services. Compliant with high secure standard ISO 27000 and SOC 1.

Limitless Range of Scenarios

Plan for the best, or prepare for the worst. Our solutions allow any collaborator to create and edit any scenarios you can imagine

Cost saving

Reduce your costs thanks to our turn key solutions. You pay only for what you need with our customs and adapted tools.

Absolute Safety

One of the most compelling benefits of immersive training simulations is that trainee errors present zero risk to veteran operators, greenhorns, or physical assets

Increase retention

Research by Stanford University and the Technical University of Denmark found that trainees using immersive learning methods experienced a 76% increase in retention

Engineering Contractors

Increase your project value by optimising design for operational safety and efficiency and optimise construction methods and scheduling by using high-quality visualisation. Simulator allows you to bring geographically-dispersed teams into the virtual plant to quickly solve technical issues. It will also help you to reduce construction errors and rework.

Owner operators

Orinox Simulator contributes in designing safe and efficient operations. Verify regulatory compliance of proposed procedures and communicate more effectively with third-party stakeholders. It will allow you to accelerate the readiness of maintenance teams and field operators prior to handover

Plant Maintenance Services

Add value to your digital asset using design and engineering data to train operators in a realistic world. The result is less risk, reduced costs, minimal start-up time, and the highest standard of safety for training purposes.

Plant Safety Services

Use your plant Digital Asset to create training videos and improve the retention of important information. Increase operator knowledge of Industrial Risk Prevention, Industrial Hazard Management, Construction/Dismantlement Risk Prevention, and Industrial Teaching Support Provider.

1. Discover ORINOX Simulator

-

Create an OCWS account

-

Start immersive visualisation

2. Try with your own data

-

If you want more and experience ORINOX Simulator on your own data create an OCWS account.Create your first Digital Asset (Project) and load your Data, it’s free up to 1GB on a non production project.

3. Start working

-

Upgrade your OCWS account with an Trainee or Scenario Plan from the console

-

Contact us more for an Enterprise plan

For more detail about ORINOX Simulator:

- Download the User Guidebook for Computer and VR